Throughout Elmelin’s history, we have always had to innovate and evolve our products and processes to adapt to the ever-changing challenges of our customers. Although our core expertise has remained in thermal and high voltage applications in the main, we’ve had to adapt our approach to incorporate innovative materials that solve new problems.

In the late ‘80s and early ‘90s, that new challenge was the asbestos crisis – around that time, we developed a range of products for the foundry industry to replace the asbestos lining they would use in furnaces.

Now, at the advent of net-zero, the challenges our customers are facing and the projects that we are involved with look very different – and as such, we have had to again innovate and evolve our capabilities to match these new challenges.

The more capabilities and innovative processes and products we develop, the more opportunities we have to work on projects that will help to combat the effects of climate change.

For us, it’s not enough just to know that we have to be innovative – we need to ensure that we have frameworks in place that ensure we are constantly evolving. Our innovation process involves weekly product and process experimentation which drives towards quarterly targets around bringing things into the development pipeline.

With a significant area of focus of the push for net-zero being the use of electric vehicles, our focus has also shifted towards creating more sustainable and efficient insulation solutions for the automotive sector.

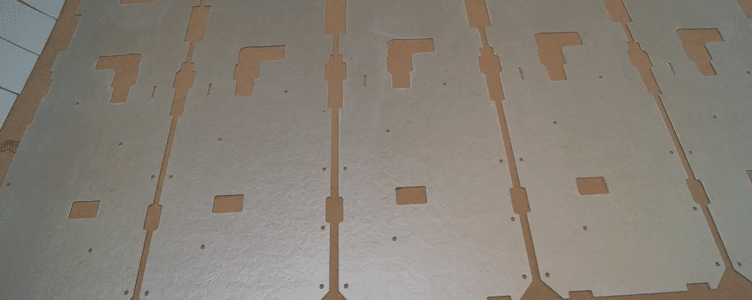

In 2016, we developed CNC machining of our microporous insulation – enabling us to make one of our first solutions for battery electric vehicles (BEVs). We commissioned a second CNC machining facility in 2018, enabling us to meet the increasing demand for more BEV solutions. As the needs and challenges of our customers have evolved, we are now looking at laser cutting technology as well as different lamination techniques – all focused around making the processes more scalable to the required volumes of the market.

As well as investing in new machinery and developing new processes, we are also looking at upgrading and further modernising our existing machinery by looking at PLC and control systems to create further efficiencies.

We are heading into an exciting new phase for our industry and for Elmelin – and we’re committed to continuing to stay innovative and always be looking for ways to make our solutions more sustainable and efficient in order to support our customers in tackling climate change.

If you’d like to find out more about our capabilities or processes – get in touch.