How mica is used in high voltage applications

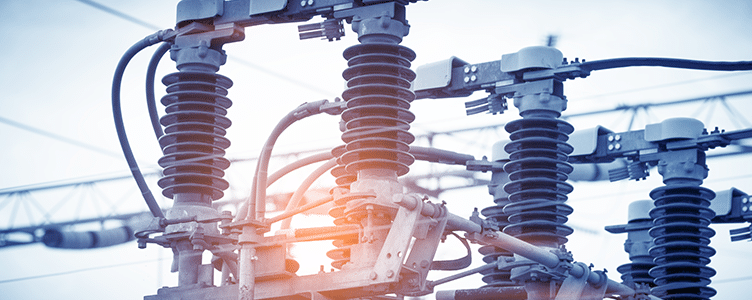

High voltage applications require a specialised and stable material for insulation. High voltages can compromise an entire circuit, as well as the safety of users and/or operators if not properly protected against, hence the necessity of suitable high voltage electrical insulation.

Mica is commonly used in a number of high voltage applications. Let’s take a look at why that is and a couple of examples of how it’s used.

The electrical properties of mica

As a material, mica has superior electrical properties when compared to other common electrical insulation materials. Mica can withstand up to 2000 kilovolts per mm of material before breaking down. It can also withstand incredibly high temperatures (which obviously come hand-in-hand with high voltages). Pure mica can withstand up to 900°C, and when reinforced and laminated with other materials can tolerate up to 1600°C. In addition to this, mica also has a high rate of permittivity (or dielectric constant), usually of around 6-7μF (Milifarads).

High voltage applications of mica

With its superior physical and electrical properties, mica is incredibly well suited to a number of applications in which users, operators or the wider system need to be protected from high voltages.

Electric vehicles

Electric vehicles (EVs) require high voltages, high currents and therefore excellent high voltage electrical insulation. The voltage in earlier versions were at 48V but as more power is required and faster charging, voltages spoken about can reach 500V and above in some vehicles such as sports cars and certain Tesla models. EVs and their chassis need to be designed carefully to protect the driver and passengers from high voltage components and systems. Mica insulation is commonly used to insulate the chassis, battery compartment and charging components in order to improve the safety of the user and to ensure that vehicles meet vital safety requirements and standards. Mica is also used with other products as thermal insulation around the battery pack and between the cells to help slow down thermal runaway.

High voltage capacitors

Possibly the most common use of mica in electrical applications is in high voltage capacitors. Mica capacitors provide reliability and stability to a circuit, enabling high precision performance. As a result, they are best suited to high frequency applications and situations in which low losses and low capacitor charges over long periods are required. In addition to its dielectric properties, mica also has low tolerance (typically around +/-1%), meaning that its capacitance typically only varies around 1% from its nominal value, making it a stable and reliable choice in circuits in which precision and performance is vital.

High voltage mica capacitors are used across a wide range of industries and applications, such as power-supply filtering, energy storage with high-current discharge and voltage multipliers. These use cases are most common in commercial electrical applications as well as in the military, where high precision and high performance is obviously key in many situations.

Elmelin have been designing and producing high voltage mica insulation solutions for over 100 years. We’ll work closely with you to design and develop a solution that addresses the unique challenges and needs of your application. Talk to us about your insulation challenge.