What is Mica?

What is mica? Whilst it may not be immediately familiar to many, it is a widely-used mineral in many industrial processes and different products. There are various mica properties that make it versatile for multiple uses. Due to its high thermal resistance, it is an excellent industrial insulation material. It offers resistance to electricity, light and moisture, making it ideal for a range of applications across different sectors.

A significant aspect of human history and progress is the story of how we have harnessed and channelled what the natural world can offer us. This includes industrial minerals such as mica.

As high temperature insulation specialists, we manufacture different mica-based products, including mica roll and mica sheets, and we use it in various thermal management solutions and other industrial insulation applications.

For those coming to it fresh, mica might seem like a mystery, simply because it is so versatile. Here we explain what it is, and some of the key ways we use it.

Properties

Mica is the name of a group of 37 layered or platy minerals that are physically and chemically similar.

The chemical makeup of mica can be described as:

X2Y4–6Z8O20(OH, F)4,

The variables are as follows:

- X is Potassium, Sodium, or Calcium or sometimes Barium, Rubidium or Ceasium;

- Y is Aluminium, Magnesium, or Iron or sometimes Manganese, Chromium, Titanium, Lithium (and a few less common variables)

- Z is mainly Silicon or Aluminium, however, it may also include iron(III) or Titanium.

These silicate (phyllosilicate) minerals form in near perfect basal cleavage. The fact mica forms in layers comes about due to its the hexagonal arrangement of its atoms. These layers can be delaminated into thin sheets, meaning they can be processed into flat films, which are also extraordinarily strong in comparison with their thinness.

Properties of these mica sheets include:

- Chemically inert,

- Dielectric,

- Elastic,

- Flexible,

- Hydrophilic,

- Insulating,

- Lightweight,

- Platy,

- Reflective,

- Refractive,

- Resilient,

- Transparent to opaque.

Two key qualities of mica minerals are that they are heat-resistant and will not conduct electricity. Combined with its lightweight flexibility and adaptability, this means it is the perfect solution for a wide range of industrial and commercial applications.

Whereas there are around 37 different types of mica, the two most important commercially used are found in our industrial insulation and other applications; these being muscovite (white) mica and phlogopite (green) mica.

Muscovite is widely recognised as the best type for electrical applications and devices. This is because it has superior dielectric strength alongside other qualities of durability, flexibility and thermal endurance.

Phlogopite is generally softer than muscovite, and is therefore suited to applications where flexibility is a big concern, such as copper commutator insulation in motors and generators.

In fact, human use of mica dates right back to prehistoric times, including cave paintings using mica minerals to create vivid red and black colours. Furthermore, the ancient site of Teotihuacan in Mexico includes a vast structure, the Pyramid of the Sun, which contains significant amounts of mica layers in its construction.

Mining for Mica

As a naturally occurring mineral, mica is extracted through mining. Obtaining sheet and block mica involves either open pit mining, or sinking a shaft along a strike. The process for mining mica is a delicate one, because, on discovering a pocket of mica, it is vital to minimise any damage to the crystals during its removal.

Small explosive charges, placed strategically, are usually sufficient to shake the mica loose from the rock-face it is attached to. Following this blasting procedure, workers hand-pick the mica for eventual transportation to the area where trimming it can take place.

Most mica mining now takes place in India and China.

A British Geological Survey found that the Jharkland state in eastern India, south of Bihar, had the largest deposits in the world. The top producer of mica is, however, currently China.

Originally, from the 19th century onwards, the USA was a big mica mining centre, especially in New England, where there were sizeable mines in Connecticut, Maine and New Hampshire.

This declined in the 1970s, with increased labour costs.

Processing

The mined mica splittings are processed into various products. This fabrication results in built-up mica and sheet mica, both of which have a broad range of applications in various settings.

Building up mica as layers results in it becoming a suitable material for industrial insulation purposes. These include power cables, which must be temperature and fire resistant, wiring for circuits and for transformers and starter motors.

In sheet form, mica serves the foundry and steel industry, the aerospace and automotive sectors and continuous process industries, among many others.

Mica and Thermal Management

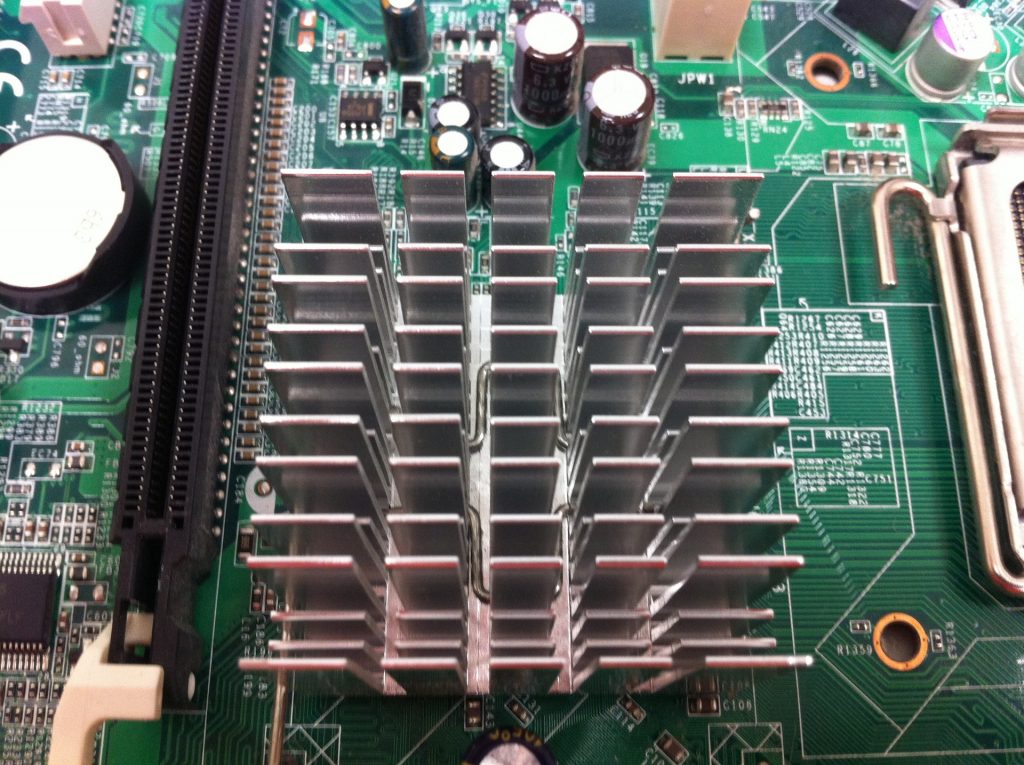

Electronic devices, circuitry, foundries and other industrial processes all depend on sound thermal management to ensure continuity and safety by dealing with excess heat. Mica has proved essential as the basis for insulation products and safety management.

It is used in a range of products because of its exceptional properties as an insulator and dielectric. It can support an electrostatic field whilst expending minimal heat energy. It can be split between 0.025mm to 0.125mm without losings its electrical properties and resists corona discharge.

It is stable up to 500 °C (932 °F), however, phlogopite remains stable at higher temperatures (to 900 °C (1,650 °F)), meaning it is well suited to situations where stability and electrical properties are required at high temperatures.

We continue to develop, refine and innovate in this area, providing bespoke thermal management solutions using mica roll laminates, sheets, tubes and components, alongside composite high temperature insulation, involving mica’s heat resistant properties combined with different materials.

How Is Mica Used In Manufacturing?

Mica is more present in your everyday life than you might think.

The next time you use a hairdryer, microwave or toaster, you are likely to be benefitting from mica’s high temperature insulation properties. In its rigid form, it is ideal for product design and manufacture.

Many consumer appliances that we take for granted only work if they have the capacity to reach high temperatures without risk to either the safety of the person using them, or their own ability to function reliably.

Used in these appliances, mica provides superb thermal, electrical and fire resistance, rapid heat transfer and mechanical strength.

Sound thermal insulation makes products more energy efficient, ensuring they can compete effectively in a crowded market, while offering consumers consistency and safety in performance.

Mica can be part of the finished product and be essential to the production process, as applied in furnace safety systems and the power electronics industry. Here, it is an excellent, adaptable and multi-functional insulation material.

Mica also has significant direct fire protection applications, providing heat resistant solutions such as lining lift and fire doors, and heat shields in vehicles and aeroplanes.

Is Mica for You?

We work closely with many different industries, using mica and mica-based products and solutions to support manufacturers and service providers. Could your business benefit from mica? Call us on +44 20 8520 2248, or email sales@elmelin.com. Or, please complete our enquiry form and we’ll get back to you as soon as soon as we can.