Elmelin’s Prototyping Capabilities

Elmelin’s prototyping capabilities mean that we can provide our varied customer-base with ways to fine-tune their requirements, while bringing down production costs and ironing out any potential problems or issues. Prototyping is both a critical evaluation tool for production, and a means of safeguarding against delays or disruptions which might otherwise be costly and damaging, both financially and reputation-wise.

Here, we look at why prototyping is so important, and the various uses of it. As such, prototyping is a capability with multiple functions, offering an enhanced service to businesses operating in different sectors.

Why is Prototyping Important?

Prototyping is a valuable tool. It can offer solutions to the production process, or help refine something that is already in production. When it comes to product development, prototyping provides key strategic support.

What is prototyping? Essentially, it means we create a preliminary model of your product. We can vary how close this is to the finished version, depending on how accurate your require it to be, and what you want the prototype to be able to test.

Prototypes vary therefore, making them versatile when it comes to testing product capabilities and effectiveness.

It may, for instance, be a case of prototyping the design of a product, focusing on its form more than its function. Or, it could be a working prototype which will not have the appearance of the finished product, but will mean you can test it under rigorous conditions before going into full production.

At the more developed end of the scale, we can produce a final prototype which is a single production run of the final product. This has huge value in allowing us to produce the equivalent of your finished product to check for quality and finishing, and that everything is as it should be.

Prototyping is like having your cake and eating it: you can have a fully functioning, working model of your product without pressing the button to launch production of the finished version. This is why our prototyping capabilities are so essential as a cornerstone in product development.

Evaluating Your Product Design

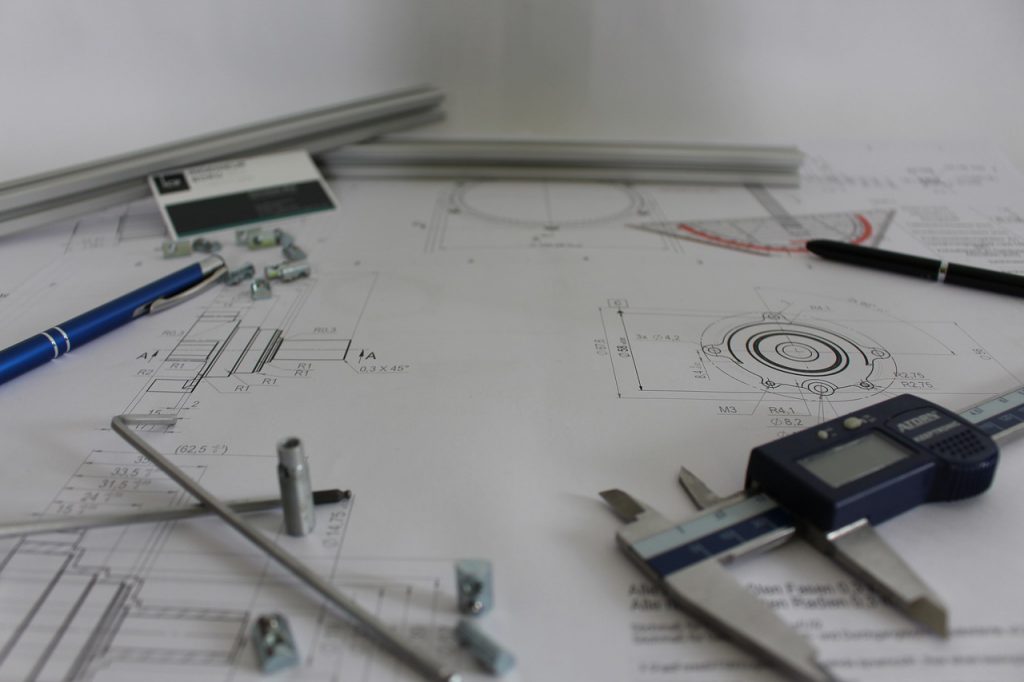

What assurances will you have that your design will work in the real world? Plans, drawings and even calculations are one thing, but reality can be quite another.

Creating a prototype means you can then see a real version of your product, and properly analyse and assess its strengths and weaknesses. Prototyping means you can strip away details that turn out not to be effective in practice, or refine other aspects of your design to make it more user-friendly.

Sometimes, on paper, you cannot see certain omissions, which, if left unattended, might jeopardise the effectiveness, or marketability, of your finished product.

Furthermore, creating a prototype allows you to test the practical aspects of your design and see if it will work when fully produced.

Mistakes in production can occur, from larger corporations to small, niche manufacturers. Prototyping before production is a clear way of protecting yourself against this happening.

Clarifying Costs and Issues

Prototyping opens a window onto the production process before you must commit to it. This offers a degree of clarity and the opportunity to develop some foresight around actual production costs and the feasibility of your product.

It means we can look at what the eventual production process will be and identify any areas where we can save on time and cost by tightening things up or even altering whole stages in the process.

With a prototype, we can see where we might alter or remove certain stages, or where certain areas of production might lead to issues with the final product.

This is all about refining what we do, to make production of the finished product as cost-effective and issue-free as possible. It can also point us towards solutions that will optimise production processes we employ.

Marketing Your Concept

A concept may be just a concept when it is on paper, which makes it harder to market to potential investors or customers. With a prototype, however, you have something tangible for the client to, literally, get to grips with.

A working prototype massively increases the marketability of a product, neatly bridging the gap between concept and reality.

Moreover, prototyping can contribute to market research, allowing potential customers to give the sort of feedback which might then result in certain vital enhancements or alterations to be made to the finished version of the product, to ensure its user-friendliness.

It may also be that you want to patent your product, if it meets the criteria of being new or unique enough. A working prototype can make the patenting process more straightforward, highlighting the key aspects of your design, and giving a patent expert a clear idea of what might, or might not, be applicable.

Prototyping Applications

With our prototyping capabilities, we can swiftly put together a model of your product using state-of-the-art modelling technology and techniques.

This works for many different sectors, including automotive, power electronics and consumer appliances.

In the automotive sector, prototyping supports an industry where the development cycle for a new car has shortened significantly, from five years to three. Prototyping has helped accelerate this process, used in the product development cycle of key vehicle components and insulation products.

For electronic products, prototyping allows for faster development and renewal time, and provides considerable savings in should a product require modification during development.

For consumer appliances, prototyping means easier verification of functions and testing for structural and design integrity.

Prototyping and Your Product

At various stages of your product’s development, our prototyping capabilities can provide cost savings and assurances that will safeguard the integrity of your project.

We can help with the collaborative process through the development of prototypes. We can gauge the feasibility of your concept prior to production development, and help reduce waste as part of the prototyping process.

As specialists in industrial insulation and thermal management, we can help you sell your idea by prototyping your product first, testing its usability and its durability.

To find out how we can help you, please call us on +44 20 8520 2248, or email sales@elmelin.com. Or, you can complete our enquiry form and we’ll get back to you as soon as possible.