Mica is a naturally occurring mineral with inherent insulation properties that make it ideally suited to a broad range of industrial and commercial applications. As a product, mica cuts across sectors, supporting specialised industries, such as foundry and steel, but also in our homes and in everyday use in consumer appliances.

Mica is versatile but also, to an extent, hidden. It is often the case that people are unaware of it, or of its properties. Here, then, we answer some commonly asked questions about mica.

Where Does Mica Come From?

As a raw crystals, mica occurs in igneous rock, which has been formed from layers of volcanic lava or magma. It can also appear in metamorphic and sedimentary rock.

Natural mica is a silicate. Silicates contain anions, which are ion charges which have more silicon and oxygen electrons than protons.

There are in fact 37 different types of mica, however, the main two are muscovite or white mica, and phlogopite or green mica. Muscovite has the better electrically conductive properties, while phlogopite is more resistant to intense heat.

Mica must be mined to be extracted. Its richest source is in coarsely grained igneous rock formations. Extraction is a painstaking process because there can be a risk of damage to the mica crystals when excavating them.

Typically, mica is mined using either open pit surface or deep shaft mining methods.

Some of the largest deposits of mica are in India, where there have been safety concerns around illegal mining activity and the use of child labour. The Indian Government has announced the intended legalisation of mica mining and is bringing in much tighter regulations.

Will Mica Conduct Electricity?

No. Mica has superior dielectric properties, which means it can transmit electrical force without conduction. This makes it an excellent insulator. Coupled with its thermal resistance, mica’s dielectric nature means it is well-suited for use in both consumer appliances and the power electronics industry.

However, mica’s stability when exposed to electricity also means that it is a key element in a wide variety of settings, protecting electrical components in aircraft and vehicles, and in widespread use by the military.

Why is Mica a Good Insulator?

Mica is widely used as an insulator because of its strength, its natural thermal insulating properties, and its adaptability.

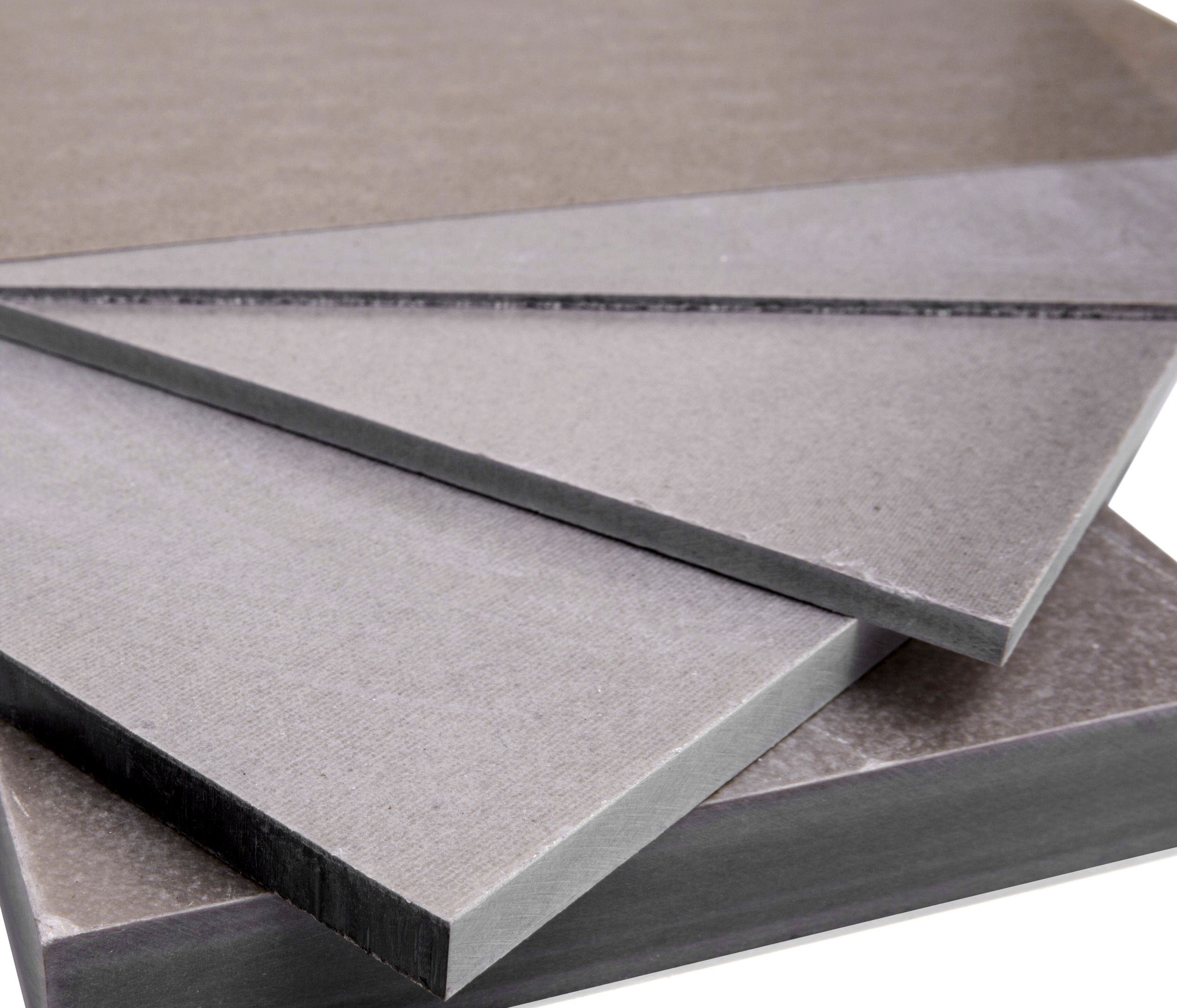

Once processed, mica is available in various product forms: as flexible or rigid sheets; in rolls; in tubes; in shapes for tooling applications and as components; and combined with other materials to form composite insulation products.

How Are Mica Sheets Made?

In crystal form, mica cleaves naturally. The atoms in its makeup are hexagonal, arranged sheet-like, so it forms smooth planes when broken. This makes processing finished mica into sheets that much more straightforward.

This manufacturing cycle involves combining mica with liquid, then added to a mesh mould where its viscosity helps it to form thin sheets.

Although mica sheets are paper-thin, they are extremely physically resilient, and contain the natural heat and electrical resistant properties associated with the mineral in its natural state.

Adding resin to mica at the processing stage gives mica sheets additional strength. This involves soaking thin mica sheets in resin then drying them. Using hydraulic presses, these sheets are then bonded together.

The result is that mica sheets can come in different grades of thickness, and can be either flexible or rigid.

What is Mica Used For?

Due to its versatility as a processed material, its resistance to heat, and its overall resilience, mica is used in a broad variety of ways, supporting different industries.

As an insulator, it is commonly used to line furnaces in the foundry and steel industry. It protects batteries and provides heat shields for the aerospace and automotive industries. It can be cut, stamped and punched into rigid shapes for tooling purposes, and as key components.

Combining heat resistance with its dielectric properties, mica is commonly used in heating elements for consumer appliances such as toasters and hairdryers, and in heat guns.

It is also used in fire protection, as a lining for lift doors and fire doors.

In petrochemical, cement and glass continuous process industries, mica provides pipe and tube insulation, as well as insulation for kilns.

The question could almost be: what isn’t mica used for, such is its sheer versatility and adaptability.

What is Mica in Makeup?

If it wasn’t already versatile enough in its various industrial applications, mica is also used in the beauty industry. Mica is found in mineral makeup.

These cosmetics contain natural minerals as an alternative to other foundation materials. Minerals such as mica will let the skin breathe while protecting still protecting it. Mineral makeup can also contain anti-inflammatory properties.

Mica is naturally resistant to water, binding to oils, which makes it good for the skin.

Makeup products containing mica include: foundation, concealers, blushers and eyeshadows.

Mica powder also has reflective properties, which, when applied to cosmetics, reflects light away from visible wrinkles and lines. Also, when used as a texturiser, mica helps to stabilise other ingredients in cosmetics, and make them more adhesive to bind them to skin when applied.

Why is Mica Good?

Mica is good for industry. It helps protect processes and people. It makes certain aspects of manufacturing more cost-effective. It helps cars and aeroplanes run safely. It protects data physically through insulation. It is essential in a great number of widely-used consumer appliances to ensure they are safe and fully functional. For fire protection, mica is an ideal alternative to asbestos.

Mica has uses in everyday life, and specialist applications for key industrial and manufacturing processes.

Could you benefit from mica? Please call us on +44 20 8520 2248, or email sales@elmelin.com. You can also complete our enquiry form and we’ll be in touch as soon as possible.