Top 6 mica sheet uses for a range of industries

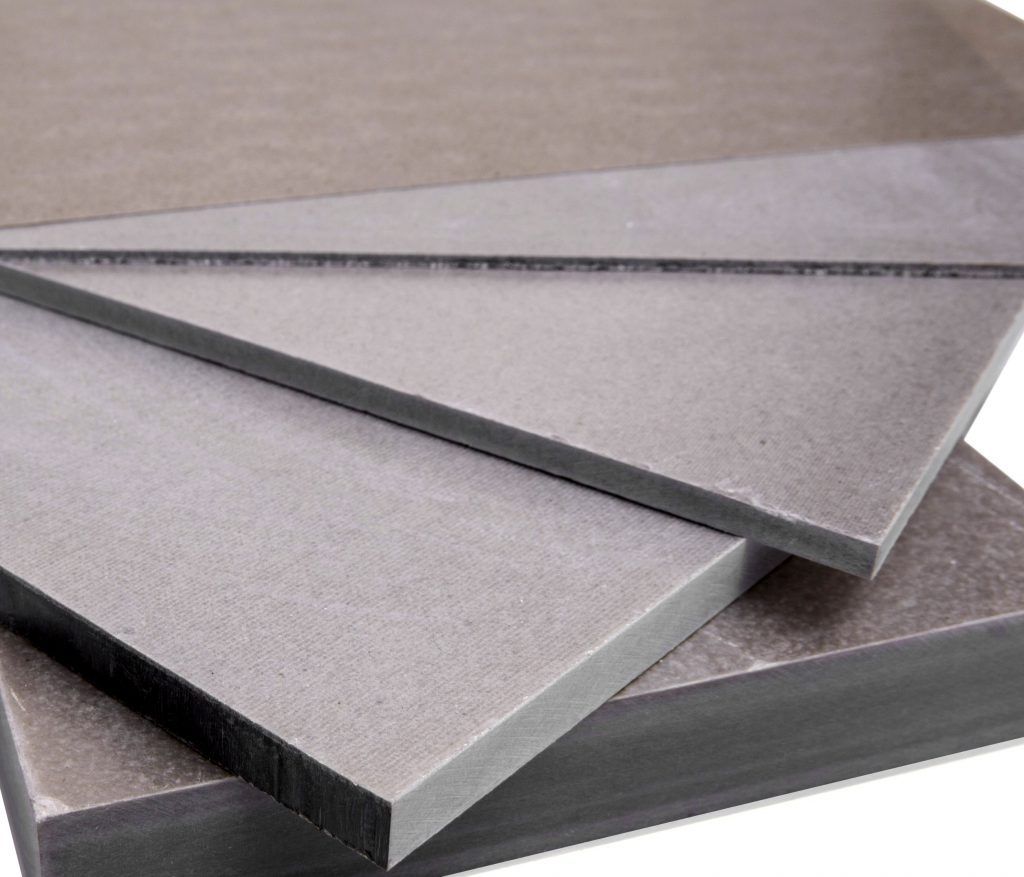

The natural cleavage qualities of mica in its mineral state make it ideally suited to production of mica sheets. This is where the mineral will break along smooth planes. Mica minerals have hexagonal atoms in sheet-like arrangements. Due to being hugely versatile, whether rigid or flexible, there are many mica sheet uses for a wide range of industries.

As a reinforcing and insulating agent, sheet mica perfectly captures the mineral’s superior insulation properties, alongside its chemical resistance and durability. Furthermore, rigid sheet mica ranges in thickness, from 0.10mm to 50mm, and flexible sheet mica 0.10 to 2mm, making it extremely adaptable for many different applications and in varied settings.

Mica Sheets-Versatility in Design

Sheet mica forms high temperature-resistant materials that are thin and lightweight, and therefore supremely adaptable. It offers high thermal resistance combined with the sort of strength that ensures product longevity. Its thinness also allows for rapid heat transfer and heating element cooling.

Mica has low thermal conductivity and good mechanical properties. These are vital for its use in supporting wire windings and heating spirals. Sheet mica also has excellent dielectric properties and fire resistance. It also has low smoke emissions.

Rigid sheet mica can be stamped, cut and punched into a huge variety of shapes and designs, from off-the-shelf solutions to specific, bespoke specifications.

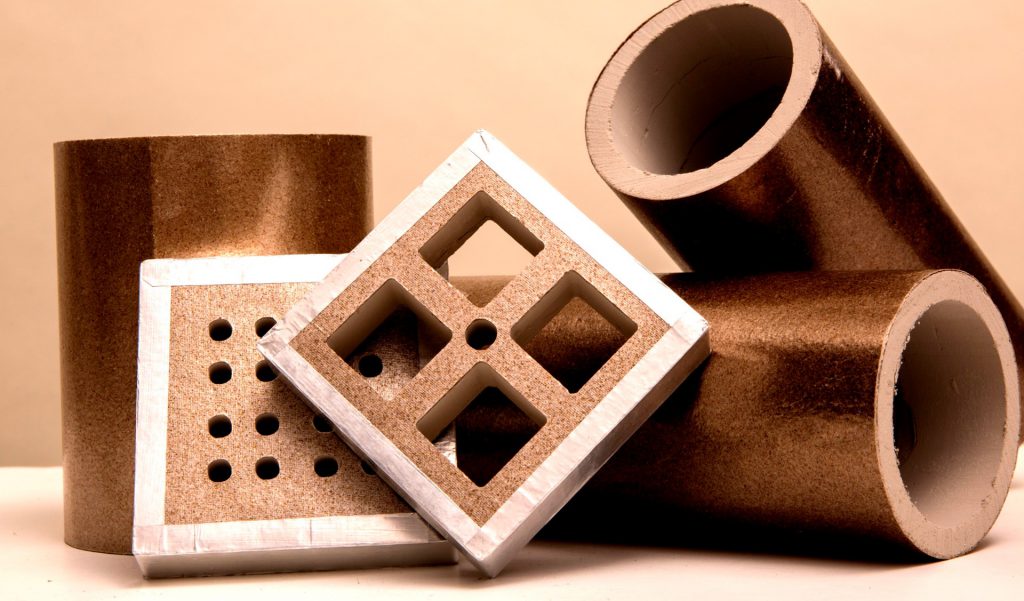

Cut and Manufactured Mica Shapes

Rigid sheet mica can be cut into insulated shapes, making it a highly versatile manufacturing material. With production based on different patterns and moulds, we can come up with custom-shaped insulation to order.

Mica is an excellent tooling application across different industries, offering advanced technical properties, incorporating thermal strength and electrical resistance.

Machined sheet mica shapes include flanges and discs. With CNC machining these shapes can come in short specialised runs where required, or larger runs of highly complex components, applying expert accuracy to produce parts at volume.

Rigid Sheet Mica Applications

In its rigid form, sheet mica is used as in furnace construction. This is different from its relining function in flexible sheet form. More mica sheet uses included furnace flooring and other areas, due to rigid mica sheets being resistant to high temperatures and providing the necessary level of insulation.

Because heat processing is integral to how foundries operate, effective insulation is essential. This is for both the consistency of the processes, but also the protection of the people working in this environment.

Sheet mica helps protect people from burns while ensuring safe working temperatures. It also prevents the build-up of condensation on cold working surfaces in foundries.

For induction furnaces, mica helps ensure robust construction, combining electrical insulation properties with thermal resistance and mechanical strength. For arc furnaces processing at very high temperatures, rigid mica sheet provides an external insulating material.

Rigid sheet mica is also widely used in household appliances and other products requiring an electrical heating element.

These appliances include items such as band heaters, toasters and hairdryers.

Many appliances are designed to produce heat quickly, using the principle of convective heat transfer. This heating process involves wound resistance wire. Mica sheet forms the rigid insulation plate for this wire.

Flexible Mica Sheets

Depending on its application, flexible sheet mica can act as a covering or an insulation foil. In muscovite or phlogopite grades, flexible mica sheet is suitable for winding or wrapping.

Heating elements in microwave ovens use flexible muscovite-grade mica, as do micro-electronic motors.

Thicker, semi-flexible phlogopite-grade mica sheets are used where high-performance thermal and voltage insulation are required, such as in the automotive and aerospace industries – in insulation pads for cars, for example.

Mica Sheets and Electronics

You will find flexible sheet mica in many electrical components and other electronics. Its versatility means we can machine it to close tolerances, ensuring its suitability for use as an electrical insulator and a thermal conductor at the same time.

High quality sheet mica is used as a dielectric in capacitors.

It can withstand temperatures up to 900°C, which is why it is ideal for providing the structure to electrical heating wire.

Furnace Insulation and Efficiency

Flexible sheet mica is essential to the foundry and steel industry as a relining material. Mica extends the life of furnace linings, which is critical when it comes to processing at constantly high temperatures.

Sheet mica’s outstanding slip pane characteristics mean that it allows for the contraction and expansion of furnace linings, reducing the possibilities of damage occurring during smelting operations.

The mica element in microporous insulation material gives it improved heat shielding properties and enhanced compressive strength.

These sheets line ladles to improve their heat volume, boosting furnace productivity while contributing to energy efficiency. Similarly, mica sheet in tundishes gives them the capacity for continuous casting.

Elmelin’s Elmtherm range of flexible sheet mica also benefits aluminium launder systems, melting furnaces, kilns and rotary kilns.

Sheet Mica to Suit Your Industry

Mica can, in many ways, seem like a miracle material, such is its sheer adaptability and durability. Whereas it is closely associated with certain key industries, such as foundries and electronics, in fact it has a far wider reach.

Due to its range of applications, it provides essential support across sectors, and makes a significant, if hidden, contribution to many different sizes of industry.

Whatever your industry, you might well benefit from sheet mica’s extraordinary capabilities. We can prototype bespoke manufacturing solutions too, to ensure our mica-based solution will work for you.

Find out more about mica sheet uses by calling us on +44 20 8520 2248, or emailing sales@elmelin.com. Or, fill in our enquiry form and we’ll get back to you as soon as we can.