Wondering what are mica shapes? Mica shapes are an example of the sheer versatility of this naturally-occurring mineral. Not only does mica have excellent insulation and thermal conductivity properties, but it is also both adaptable and durable in rigid sheet form.

We can manufacture mica can into different shapes, making it an ideal material for vital parts and components in various processes, devices and machinery.

This means that mica’s technical properties are applicable across different sectors and in diverse settings, depending on individual requirements. Elmelin provides shaped insulation using patterns, moulds, and machine cutting, pressing and stamping processes.

The finished results can be found in machinery, equipment and other devices, and as essential electrical components.

Advanced Technical Capabilities

For a broad range of tooling and applications, mica shapes offer superior thermal insulation and electrical resistance. Mica’s advanced technical properties have made it the first choice in many industries when it comes to essential working parts and an insulating material.

It also fulfils a vital role as a safe substitute for asbestos where fire resistant and protective properties are a major requirement.

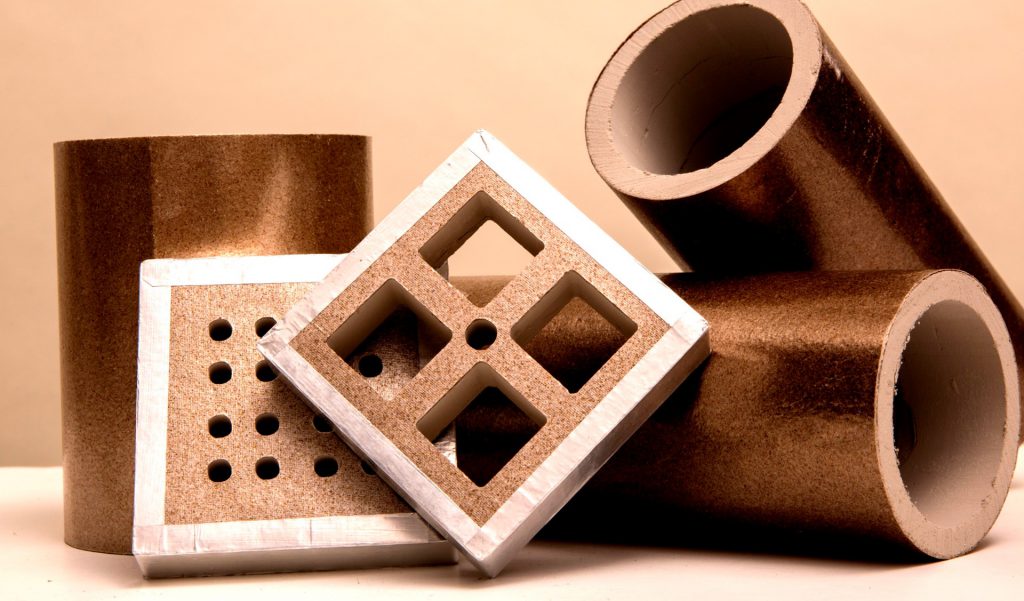

Composite mica shapes come in many different sizes and thicknesses, and we can manufacture to order, including small, complex parts in large runs. State-of-the-art CNC machining gives us this kind of capability, so that we can combine precision finishing with volume. This mass customisation is an essential element in many strands of modern manufacturing.

We believe the possibilities are near-limitless when it comes to providing customised mica shapes and specialist fabricated parts.

All our mica shapes are quality tested to ensure they meet stringent ISO 9001 certification requirements, or other standards as specified by our customers.

The Benefits of Mica Shapes

Where vital machined parts require a high tolerance to heat, stress and electricity, mica is the solution. It works for processes and finished products alike, being both resilient and extremely tough.

With our CNC machining for milling, cutting and turning we produce shapes such as flanges, discs, tubes and washers, at whatever size is required, with scalable production runs.

The benefits to our customers come in the form of increased cost-effectiveness, energy savings and better productivity, with composite mica shapes helping to ensure that their processes are fast and efficient, with minimal downtime.

Machined and Other Mica Parts

Machined parts made from mica composite include slot insulation pieces, slides, screws, rods, and vacuum moulded parts.

We have a complete processing technology package dedicated to this production, encompassing design, moulding, machining, stamping, punching and casting.

We can take your requirements from consultation through to planning to final machine parts or other specific shapes.

Where, for example, you require screws or rods for applications where they will be in immersed in dielectric liquids, or they require a high level of resistance to chemical agents, then customised, composite mica shapes can provide the solution.

Mica Insulating Washers

The mica washer is ideal for electrical applications in a wide range of settings, across different industries. Its familiar shape is circular with a hole punched out of the middle. In fact this uniqueness of form makes the washer supremely adaptable.

Being made from mica gives these washers certain special qualities. They have low thermal expansion, low thermal conductivity but a high dielectric resistance and sound mechanical strength.

These combined qualities mean the mica insulating washer is the perfect fit as a component in various pieces of machinery and equipment and is especially suited to the power electronics industry.

Mica Shapes in Electrical Components

Mica is a common insulating material with uncommonly high-performing qualities. It is very stable, even in situations where it is exposed to the elements or made to withstand extreme heat. At the same time as it is tough, it is also easily cut and shaped to form different parts.

Consequently, you will find mica as an insulator in many kinds of electrical component, including capacitors, diodes, power transistors and other semiconductors.

As precision-punched parts, mica insulators dissipate heat away from semiconductor devices but also help keep them cool. They have low moisture absorption and a high level of resistance to surface leakage.

Capacitors are vital in both large-scale electric grid systems and small-scale electronics. They store power and sort out differences in timing between current and voltage.

Mica capacitors are assembled from sheet mica layers, shaped to fit by cutting to size, then coated on both sides with metal.

Mica Shaped to Fit Your Needs

Elmelin’s versatile machining service provides our customers with exactly the customised mica shapes they need, in the quantities they require. We can provide parts that vary in complexity.

We offer cost-effective solutions that are scalable, so whatever kind of production run you require, and however complex the finished parts, we are confident that we can meet your specific needs.

The flexibility and serviceability of our machining and shape-making capability mirrors these same qualities that mica itself possesses as a material, and which make it such a widely-applied insulation solution across different sectors and industries.

Discover more about mica and give us a call on +44 20 8520 2248, or email sales@elmelin.com. Alternatively, you can complete our enquiry form and we’ll get back to you as soon as soon as possible.