Why Do You Need Mica Slip Plane For Induction Furnaces And How Do You Choose The Right Product?

Mica slip plane at its simplest can be thought of as an insurance policy to protect your induction furnace. Much like insurance, mica isn’t something you need but it is advisable to have.

If you make the wise decision to opt for mica, you then have to decide the type of mica you need, as various mica products do different things.

To help you make this decision, it’s important to understand the history of the use of mica and the product’s evolution. To help you make an informed decision, we’ll outline what to look for in a good mica slip plane.

Whether you choose to use our mica or not, we hope this article helps you choose the best product for your foundry requirements.

The History Of The Mica Slip Plane

The use of induction energy to melt metal has been around as a concept since 1870. The first patent was filed for an induction furnace around 1900. However, real growth in the use of induction furnaces started in the mid-1980s and accelerated through to the mid-1990s.

Since the year 2000, there have been further advances in the sector with many companies starting to recycle and melt scrap metals. So, how the melt behaves and how the sintering process works is a relatively new science.

Here at Elmelin, we devote a large percentage of our resources to work with the industry-leading furnace OEMs and refractory companies. This enables us to develop the best mica for the job in your induction furnace.

What Is An Induction Furnace?

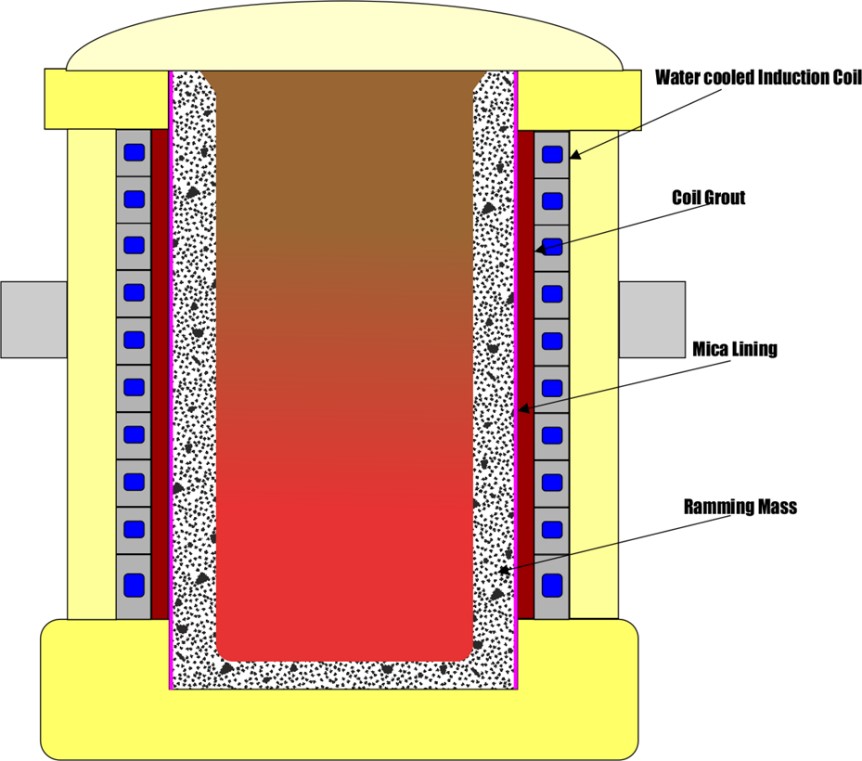

An induction furnace is a complex piece of equipment that uses the process of heating an electronically charged product – usually metal – by electromagnetic induction, generating heat in the substance to be melted by eddy currents. Mica can play an important role in insulating induction furnaces.

The induction coils are cooled using water running in the tubes and held in place and lined with a coil grout. This is a rough mortar type product.

Inside the furnace, the metal is put in a shaped crucible or bespoke ramming mass; these products are manufactured in their simplest form using silica sands and increasing in complexity.

All refractory companies have their specific and proprietary products designed to increase the number of charges in your furnace. The mica sits between the refractory and the coil grout.

The Use Of A Mica Slip Plane Within An Induction Furnace

This is where the insurance policy concept comes into force. When the furnace is new and no production has taken place, the coil grout is smooth and positively shaped in a slight V so the ramming mass can slide up and down.

It does this each time a charge is made and can move up to 5% of the crucible height. As the number of charges increases, ramming mass will sinter.

If the foundry manager or operator does not detect the linings state of sinter, the ramming mass could become lodged tight up against the coil grout. Without mica, this becomes a costly maintenance job and requires the entire sintered lining to be removed by hand and the coil grout repaired.

During the life of the refractory, mica protects the furnace in two ways. Firstly, it extends the lining life by allowing it to move freely up and down through expansion and contraction.

Secondly, it protects the coil grout from damage by allowing the lining to move freely and more importantly, by providing a slip plane along which the refractory slides out.

So, as an insurance policy, the financial advantages of mica are:

- Improving the throughput of your induction furnace

- Reducing downtime

- Improving relining speed

- Reducing coil grout patching

It improves throughput by extending the lining life. Reduces downtime by making the push-out quick and reducing the time required to reline the furnace.

Mica is quick to install and easy to apply as an insulation material. Finally, reducing the potential damage to the coil grout ensures less patching is required.

Which Type Of Mica Slip Plane Do I Need?

Today we make many different forms of mica to protect against different issues, in broad product category terms there are five categories. When selecting the mica, understanding the make-up of the product is important.

We always talk of pure mica content in grams per square meter, this excludes resins and fibreglass.

Our pure mica foil products are made from pure mica reinforced with high-temperature silicone resins. This material is the best mica slip plane and the highest mica content product we manufacture.

The pure mica content is typically above 600 gsm of mica. We can supply this product as a pure mica product (MF material) or one with a thin layer of glass in between two layers of mica (MGM material).

Glass Mica

Our glass mica products are designed to increase the handling durability of the mica product. Glass mica should still have a high mica content such as 300-450gsm per mica layer. Here at Elmelin, our best sellers are our GM type materials with glass on one side.

The industry has many players who use cable tapes to make up layers of mica slip plane, which essentially is just glass with minimal mica per layer (as low as 70-90 gsm).

While this product may be cheaper, it is not designed as a slip plane and the products will not give you the security you are paying for. When we talk about our GSM content, we only refer to mica and not the glass layers.

Kombi Mica

Kombi mica is the response to an industry requirement where some companies, typically those using silica-type ramming mass, choose to put in an extra layer of insulating paper. The reason for this is insulation paper reduces the power consumption required to maintain a specific melt temperature.

Our products are available with 1mm-3mm of bio soluble non-hazardous insulation paper bonded to the mica. We include a very thin glass layer to make the material more robust.

Typically, there should be one robust layer of mica supporting the insulation paper. Unfortunately, cheap imitation products exist. These tend to be cheap electrical cable tape glued onto the insulation paper. There will be multiple layers of very low content mica tapes.

Elmesh

Elmesh is mica with a metal mesh inside. The mesh can be used as a sensor to signal the crucible is wearing thin. The mesh can be connected to the earth leakage system to provide an early warning of a failure.

This product is often used as a low-cost lining wear detection system as it allows the furnace to shut down operation before the coil or coil grout is damaged.

Vapourshield

Vapourshield is a response to a modern foundry problem of metal vapour deposition. This is caused when foundries have been burning more scrap; particularly zinc.

The design of the product prevents the zinc from penetrating the coil or coil grout and can significantly enhance the life of your refractory and coil.

This is a special application and needs to be designed carefully with your refractory supply partner. The furnace size, power consumption and frequency will have a bearing on the overall design.

Advantages And Disadvantages Of Different Mica Roll Products

| Mica Type | Advantage | Elmelin Product | What to watch out for |

| Pure mica | Best mica slip plane typically 600gsm mica layer. Can be difficult to work with on site as it tears. | MF or MGM products | Typically pure mica with perhaps one very thin layer of glass in the centre |

| Glass mica | Slip plane with enhanced mechanical strength. Typically if one sided mica layer is 300-450 gsm in one layer | Our GM products are our main sellers. Older designed products are SMS | Check the mica content. Many companies brag of high mica content, but the product is mainly glass as it comes from cable tapes and the mass is the total product mass, not mica content. |

| Combi mica | Slip plane and paper insulation with high mica content 200gsm to 300gsm in one layer. | Our CM and CSML product are available in 1mm to 3mm paper. | Ensure the insulation paper is bio-soluble and the mica is in one paper layer and not multiple layers of glass. |

| Elmesh | Provides early warning of lining failure and metal penetration alarm. | Elmesh is the product with a metal mesh inside the mica. | Typically only supplied by Elmelin partners |

| Vapourshield | Prevents metal vapour deposition and when connected to the spider can provide a metal penetration alarm | Vapourshield is a patented Elmelin product | Patented product from Elmelin partners only. |

Mica is a safe, asbestos-free slip plane material. Here at Elmelin, our products contain high single layer mica content, which provides excellent slip plane characteristics.

If you have any questions about mica slip plane or would like to know more about our products, you can contact us on +44 208 520 2248 or e-mail sales@elmelin.com.