This story could be titled the evolution from the industrial revolution to the CNC machine age. Elmelin has been around long enough and has evolved enough times to have processes from both. Our core competence is one of reinvention. At its heart is mica.

Author of Competitive Strategy, Michael Porter, argues that strategy is about the competitive position. About differentiating yourself in the eyes of the customer and about adding value through a mix of activities different from those used by competitors. This is something we think about constantly as a business and it is driven by the customer requests we get.

The History Of Elmelin

Elmelin was founded in 1912 and initially manufactured mica light filaments for gas lanterns. A little-known fact is our home city of London still has around 1500 operating gas lamps. This link provides a lovely video about the keeper of the maps from British Gas.

Obviously, we have had to evolve from those days and have done so in many ways over the years. Much of the mica insulation used in the early days was hand-laid mica sheets using silicates and shellac resins to hold the product together.

We also stamped washers out of mica and manufactured v rings for commutator mica. We have prided ourselves on keeping this link to manual manufacturing and providing our employees with constant skills development.

Evolving To Mica Insulation For High Voltage Electrical Installations

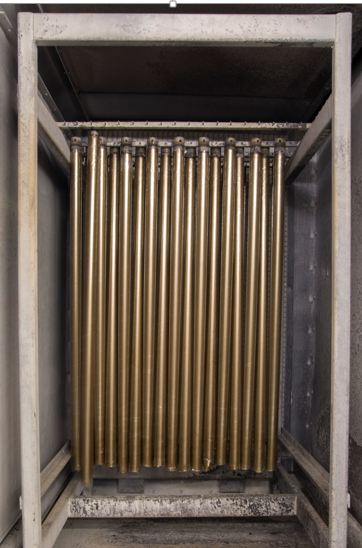

In the 1980s, we started experimenting with mica paper impregnation to manufacture mica tubing for high voltage electrical installations. This was the first step in the continuous process, and we built our first paper impregnation machine. The development of these products and processes also helped us get into the manufacture of tubes for heat guns.

The rolling of tubes is a multi-step manual process undertaken in a similar way today as it was done when we started. Here at Elmelin, we remain the only manufacturer of mica tubes in the UK and one of the few in Western Europe.

The introduction of the impregnation line in the 1980s was very timely. The induction furnace market was taking off and much of the industry lined their furnaces with a layer called a slip plane. This made for easy removal of the crucible. The problem was much of this material was either asbestos or just fibre cloth.

Developing Mica Laminating Processes

As the industry embraced mica as a potential slip plane, Elmelin was able to develop laminating processes to complement its impregnation technology. This led to multiple lines of products supplied to the steel and foundry industry.

Elmelin is supported by multiple partners in this space who understand the furnace industry. Today this represents a big proportion of our sales and the products are exported throughout the world.

Moving To CNC-based Thickness Shaping

Elmelin has always had capabilities to shape mica in different ways. In the early 2000s, customers were starting to use microporous insulation with very low thermal conductivity. The industry challenge was getting this in thinner sheets or very precise thicknesses.

Here at Elmelin, we responded by developing our first CNC-based thickness shaping machine. From that our Elmtherm range was formed.

As we understood this industry more, we realised there was a gap for more complex shapes, and we purchased our first CNC milling facilities. This required a lot of understanding about machining and the extraction of the dust.

Innovative Mica Insulation Barrier Solutions

24 months later, the capabilities we had developed helped us to build the first prototypes of an insulation barrier between battery packs that went into an electric vehicle to stop thermal runaway. Our design concept was used in the production vehicle, which went into production 18 months later.

Elmelin has since undertaken multiple projects in this space and we have had to evolve what we do and how we do it. In June, we installed a state-of-the-art CNC milling machine with a 3m-2m bed, which able to machine all types of insulation we work with.

We have also upgraded our quality system from ISO 9001, for which we are audited and licenced to being IATF16949 compliant.

In conclusion, Elmelin has evolved from artisan hand made products through to CNC quantity applications. Our core competences remain forming, laminating and shaping mica and other insulation products to form highly insulating thermal and electrical barriers.

Get In Touch

We would welcome the opportunity to discuss your requirements. Please contact us on +44 208 520 2248 or e-mail sales@elmelin.com