Elmelin’s Compression Pads Plus: All you need to know

The safety of electric vehicle batteries is a grand challenge of modern automotive engineering. Over the past few years we have seen a sharp increase in the number of electric vehicles on our roads. This has been for numerous reasons; better technology, cheaper running costs, increased accessibility to charging stations and increasingly at the forefront of people’s minds, cleaner emissions and reduced pollution.

Car manufacturers and consumers are recognising the importance of reducing both harmful emissions and our dependence on fossil fuels. Each day, we are reminded of climate change, ecosystem disruption and irreversible damage to the environment. There has been a shift in environmental awareness and people are beginning to switch to electric vehicles and moving away from petroleum-based vehicles.

At Elmelin, we have certain core values that we abide by and apply into our products. Sustainability is one of these values, and we’re passionate about the development of safe, reliable, and sustainable EV batteries. One of our key products is Elmelin’s Compression Pads Plus, a solution for EV batteries that improves the safety, performance and lifespan of a battery by helping to maintain suitable pressure on the battery pack whilst simultaneously providing thermal and electrical insulation.

Where Elmelin’s EV battery solutions began

Between 2015 and 2020, the number of registered battery electric vehicles in Europe grew from 87,000 to 747,000, and this trend has continued through 2022 and onwards. It’s only been in recent years that electric vehicles have become so fundamental and a major industry we have the honour of providing solutions for.

Back in 2016, we were tasked with developing passive fire protection for electric vehicles and construction. Passive fire protection is a crucial safety feature and the first line of defence to significantly reduce the spread of fire and smoke. Just as we do now, we utilised mica’s superior thermal properties to produce high-performance passive fire protection solutions.

In electric vehicles, lithium-ion batteries with high-density energy operate at extremely high temperatures, increasing the risk of malfunction and harm to occupants in the vehicle. In order to help ensure the safety of vehicle drivers and passengers, we designed passive fire protection solutions specifically for electric vehicles. These had the same principle of slowing down the spread of fire, but focused on slowing the spread and keeping it away from the battery compartment.

The passive fire protection solutions we developed continued to evolve and change over the years. New enquiries were coming through our door and so began our research and development into new technologies and solutions, namely Elmelin’s Compression Pads Plus.

Regulation changes

In 2020/21, regulations changed and the fire safety of batteries became vital to manufacturers in the automotive industry. These regulation changes allowed the industry to understand more about fire safety and how we can develop solutions for reducing the risk of serious incidents. We further benefited from these changes, and our Compression Pads Plus solutions could be developed to greater extent and improve safety, performance and useful life of EV batteries.

The focus for developing EV batteries was originally on power density rather than fire safety. There is now a balance between the two, leading to safer batteries that still perform at high levels. This current balance is to have sufficient fire safety and abrasive resistance from cell-to-cell and pack-to-pack, essentially ensuring fire protection that doesn’t convert energy from one cell to another.

The issue with power density is that compression needs to be performed in the correct way. Different materials can be used to withstand different temperatures, each with their own unique compression ratings. Therefore Compression Pads Plus can be made to customer needs and specific application requirements, rather than being limited to shelf products.

What we offer

Elmelin’s Compression Pads Plus use powerful compression technology to allow for safer, high performance EV batteries. Compression pads maintain pressure on a battery pack to ensure secure electrical and thermal connections while allowing the package itself to expand and change shape during operation, and between battery cells to compensate for tolerances and breathing of the cell.

When a battery is in operation, the chemistry of cells involves different metals and acids in both dry and liquid forms. Crystallisation occurs within batteries and compression pads keep this chemistry as compact as possible under compression, in order to avoid irreversible crystallisation. The materials used are required to be hard enough to compress but soft enough for the cells to breathe.

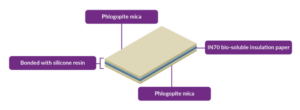

Elmelin’s Compression Pads plus are formed of phlogopite mica layers with a layer of IN70 biosoluble insulation paper sandwiched between them, and bonded with silicone resin:

When compared to other compression pads on the market, the unique composition of Elmelin’s Compression Pads Plus offer superior thermal resistance and dielectric strength. Our compression pads can withstand up to 1000°C, 5x that of other solutions, and up to 2000V, 10x that of other solutions.

As well as having outstanding thermal and dielectric properties, Elmelin’s Compression Pads Plus are non-combustible, bio-soluble, non-hazardous and can be made to your requirements. The phlogopite mica used in the layers can be different thickness depending on your individual requirements.

Conclusion

At Elmelin, our goal is to provide multiple industries with high-temperature insulation solutions for a range of applications. Elmelin’s Compression Pads Plus are one of many solutions we develop, each with safety, performance and sustainability at the core. Going forward, we’ll continue to research, learn and collaborate with other highly experienced engineers and manufacturers.

There will be new challenges and opportunities in the coming years and we look forward to reacting, adapting and delivering on outstanding industrial insulation solutions. If you would like to find out more about our products and solutions, or have a specific customisation project to discuss, then please do get in touch.