3 ways mica can be adapted and used for various applications

Mica is an incredibly versatile and flexible material. Due to its unique physical, electrical and thermal properties, it makes an ideal insulation material. Across the broad requirements of industry, there are billions of machines, components and products that need to be insulated – all requiring a slightly different approach, and slightly different material. Because mica is so versatile, it can be adapted into various applications through cutting, shaping and combining with other substances to create unique insulation solutions.

Here are 3 ways in which mica is commonly adapted for use in various applications.

Shaped mica

Mica forms in incredibly thin sheets and has high tensile strength, meaning it can be easily cut and shaped. As technology in various industries evolves, and in many cases components and mechanisms become smaller – equally associated insulation solutions must be smaller and more precise.

Techniques such as CNC milling, laser cutting and clicker pressing allow mica to be produced in large quantities in very precise shapes, and to exact measurements. These shaped mica products are commonly used in high voltage transformer and switchgear applications, where precision parts are needed, often in bulk. Additionally, pure mica can withstand up to 2000 kV per mm, making it ideal for high voltage applications.

Shaped mica is also becoming more and more useful in the automotive industry, where the mandate to move to electric vehicles is forcing innovation in battery technology. Mica shields can be used in automotive batteries to provide vital insulation which helps to slow down the process of thermal runaway.

Mica roll

Mica has superior thermal properties. Pure phlogopite mica can withstand up to 1C – but it can also be bonded with other insulating materials to form a stronger and even more effective insulation material. A common application for this is mica roll – in which mica is combined into a laminate with another insulating material and produced in rolls with a thickness anywhere from around 0.4mm to 3.3mm. The materials mica is combined with could include glass fabric, glass tissue, silicone, and CMS (Calcium Magnesium Silicate), to increase the temperature that the material can withstand and to reinforce its strength.

This type of product is commonly used in induction furnaces as a slip plane. Because it’s thin and flexible, it’s easy to install. And because it has superior thermal properties and is extremely durable, it can help to extend the life of the furnace lining.

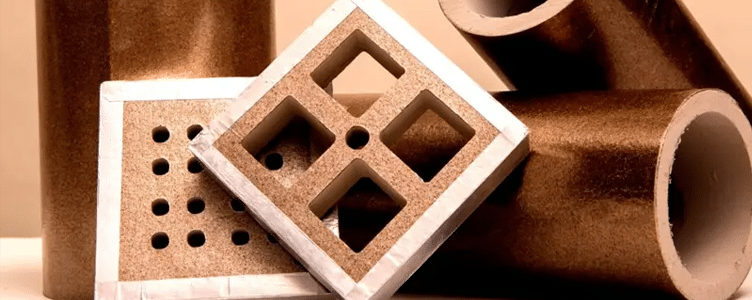

Rigid mica and formed components

Although it is a flexible material which can be worked into various forms which makes it lightweight and easy to work with, mica also has high tensile, compressive strength, and elastic tenacity, meaning it is strong, durable and responds well as structural and insulating support. This means that it can be easily incorporated into more rigid applications – such as tubes, brackets and spacers.

Mica tubes are common in many appliances, such as hair dryers, air blowers and heat guns, acting as an insulation sleeve and protecting the core heating elements. In addition, due to their superior electrical and thermal insulation performance, they can be used in larger electrical motors and smelt furnaces.

Mica sheets can be shaped around a form and function in much the same way as tubes. Which product is used will depend on the design and space of the item that needs insulating.

Both rigid mica tubes and mica sheets can be specially manufactured to be waterproof – meaning that they can withstand the elements and keep their superior insulation properties for longer.

Elmelin have been working with mica as an insulation solution for over 100 years. We can form it into tubes, sheets, laminate rolls and precision-cut shapes. Do you have an insulation challenge that requires a tailored solution? Get in touch to discuss how an innovative mica-based solution could help you.