Mica insulation has impressive thermal and electrical properties making it a suitable material to solve many engineering challenges. Elmelin have developed processing capabilities to cut, stamp and shape mica to address these challenges. We frequently work with clients to design and cut mica to fit their bespoke applications. Due to its versatility, mica is highly adaptable, so with that in mind, let’s take a look at some of the common applications of cut and shaped mica.

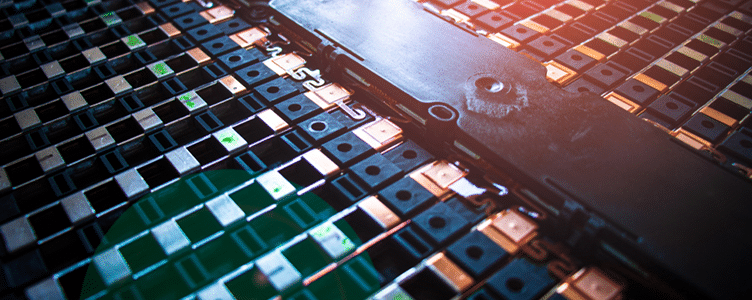

1) Battery insulation

Cut or shaped mica sheet is frequently used to provide fire protection and insulation for a battery pack and/or in between battery cells. This is increasingly common in battery-powered electric vehicles, where a large, high-density lithium-ion battery pack requires a carefully designed solution to ensure the safety and efficiency of the vehicle.

Mica sheet can be combined with other materials to improve its performance, resilience and electrical and thermal insulation capability. One example of this is compression pads. In our solution, Compression Pad Plus, mica is combined with layers of biosoluble paper bonded with silicone resin to form a rigid sheet which maintains pressure on the battery pack. This allows the pack to expand and change shape during operation. In addition, the material can slow down thermal runaway and provide a level of fire protection between cells.

2) Mica components

In addition to being cut into rigid sheets, mica is also ideal for cutting and mass-producing as small, shaped components in both thermal and electrical applications. In electrical systems, mica is often used for transistor parts, heating elements in household appliances such as toasters, kettles, light fittings and hair dryers, as well as cut discs, which are used in communication devices and breathing apparatus.

Mica’s superior performance at high temperatures also makes it an ideal material for gaskets. Mica gaskets can be found in turbo chargers, turbines and exhausts. Mica is also commonly shaped into washers, which are used in a variety of electrical and thermal applications across a range of shapes and sizes.

3) Custom applications

As mica is highly flexible and versatile and can be cut to any shape or size, many components and solutions can be made to order. At Elmelin, we frequently work closely with custom R&D departments to develop bespoke solutions and produce prototypes that can be thoroughly tested in helping them to solve very specific challenges. This innovation is vital as technologies advance and change, but is particularly prevalent and important in battery technology. Being able to use a versatile material like mica and also combine it with other materials to further enhance its performance and capabilities opens up more possibilities for applications it can be used in and for.

Elmelin are committed to a truly consultative and innovative approach and will work closely with you to develop a cut or shaped mica insulation solution that serves your exact needs or challenge. If you’d like to discuss your unique insulation challenge with us, get in touch.