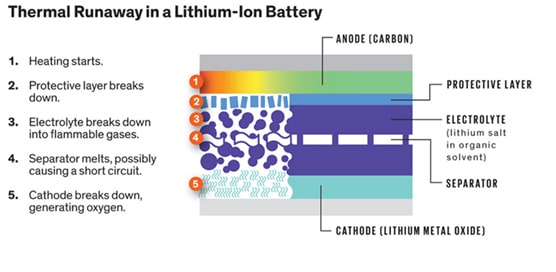

Thermal runaway is a significant risk present in batteries. It occurs due to a battery cell failure of some kind, occasionally as simple as the separator between the anode and the electrolyte breaking down. This generates an increase in temperature, creating a chain reaction in which more energy is released, causing the electrolyte to break down into flammable gasses. Once the separator melts, the cathode of the battery breaks down further fuelling the fire with oxygen, triggering an uncontrolled positive feedback loop, often leading to a destructive result. The risk of thermal runaway begins at 60°C and becomes extremely critical at 100°C. Once the process has begun, temperatures rise rapidly within milliseconds – creating temperatures of around 400°C. It is particularly prevalent in lithium-ion batteries.

In this post, we’ll explore the risk of thermal runaway in lithium-ion batteries, and how this process can be slowed in electric vehicle batteries to increase safety.

Thermal runaway in lithium-ion batteries

If handled or operated improperly, thermal runaway can occur in batteries, causing them to overheat, and eventually catch fire or explode. Lithium-ion (LI-ion) batteries are particularly susceptible to thermal runaway. LI-on batteries have an extremely narrow operating temperature range of between 15 and 45 degrees. Outside of these operating temperatures, the stability and functional safety of the battery is highly compromised. LI-ion batteries are commonly used in portable devices – such as mobile phones, laptops and cameras, power tools, and electric vehicles.

Thermal runaway in electric vehicle batteries

Continued development and market trends in electric vehicle batteries require them to charge quicker and last longer. Technically, this requires greater energy density within the battery – which makes Li-ION batteries ideal. However, this higher energy density means that thermal management becomes a critical discussion point from a safety perspective – which is obviously of the utmost importance when it comes to vehicles, and strictly regulated within the industry.

Because a larger amount of power is needed in electric vehicles, it’s common for many smaller Li-ION batteries to be connected in a parallel circuit, which is more efficient and effective than charging a large single battery.

As such, if thermal runaway occurs in a LI-ion battery in an electric vehicle, there is the additional risk of a chain reaction being created between the batteries, especially if the thermal runaway is not controlled and temperature is allowed to increase throughout.

Thermal runaway is a significant risk in electric vehicles. Ostensibly, there are a lot of situations in which the batteries might exceed their operating temperatures and reach the critical 60 Degrees C. If an electric vehicle is involved in a collision, this can cause damage to the battery which will in turn cause an internal or external short circuit. This leads to an increase in temperature and inevitably, thermal runaway. Thermal runaway can even be caused if a vehicle is subjected to high temperatures, such as being left running or left in direct sunlight, and if charged incorrectly.

Addressing thermal runaway in electric vehicles

Thermal runaway cannot be prevented in the event that the battery short circuits or reaches the critical 60 degrees C. The thermal energy can be quickly transferred to neighbouring cells in a fatal chain reaction – potentially leading to explosion. It is a positive feedback loop that once started can’t be stopped, and the energy created has to go somewhere. In order to try and make the LI-ion batteries in electric vehicles safer, insulation can be used between the battery cells to slow down the process of thermal runaway, or at least prevent the temperature outside the battery increasing if the whole pack is insulated.

As previously mentioned, this will not prevent the process once started or prevent the inevitable result of fire or explosion in the event of a single cell failure – but what it will do is slow down the temperature increase and therefore the reaction within the battery pack, giving the driver and passengers of the vehicle more time to exit and move to safety.

Mica as an automotive insulation solution

Elmelin use mica laminated sheets to create thermal barriers between battery cells in an electric vehicle. Mica is an excellent insulator and can withstand temperatures of up to 1000 Degrees C. Mica can also be combined with other insulation products to further slow down thermal propagation. Combining these solutions with the right battery management system (BMS) means you will be able to significantly delay thermal runaway and give the occupants of the car more time to get to safety.

Mica laminate sheets can also be used to house the battery to provide additional explosion resistance and prevent the heat from spreading more quickly throughout the internal mechanics of the vehicle and further delaying thermal runaway.

If you’d like to find out more about our insulation solutions for electric vehicles and other automotive applications, get in touch.