When it comes to selecting the right insulation solution for an electrical application, it’s important to understand the dielectric capabilities and properties of the material or materials being used.

A dielectric material is one which is a poor conductor of electricity, but can support electrostatic fields. This means that if the material is exposed to an external electric field, the substance becomes polarized. This allows it to store electric charge, making it a poor conductor, but a good storage medium.

Another important property of dielectrics is their ability to support an electrostatic field which dissipates minimal thermal energy – the lower the dielectric loss (the amount of heat dissipated when charged) – the more effective the material will be as a dielectric. Also, an important property is the dielectric constant, sometimes known as relative permittivity. This means the ratio of the amount of electrical energy stored in a material by an applied voltage, relative to that stored in a vacuum.

A lower dielectric constant tends to be desirable because substances with high dielectric constants have a tendency to break down more easily when subjected to intense electric fields – hence why materials with low and moderate electric constants are typically used in high voltage applications.

Dielectric materials are split into types based on their state – solid, liquid, or gas. Each type has differing dielectric properties and, due to its state, different applications.

Solid dielectrics

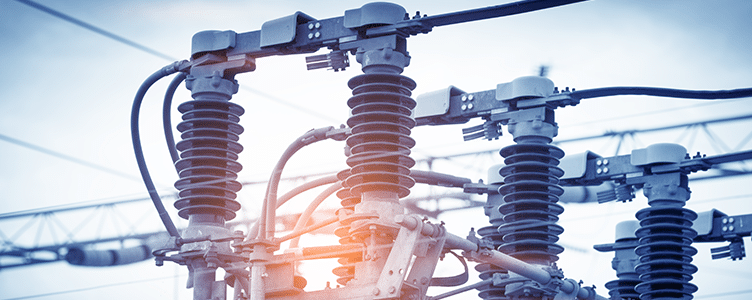

In practice, most dielectric materials tend to be solid. They are used as insulation in capacitors, high voltage transformers and switches, overhead lines and cabling. Solid dielectrics have a moderate dielectric constant. Solid dielectric materials include:

- Inorganic materials such as ceramic and glass

- Plastic films (e.g. Kapton)

- Rigid fibrous reinforced laminates

- Resins, varnishes and silicones

- Vulcanized adhesive tapes

- Mica

- Textiles and fibres (e.g. Nomex)

- Elastomers and rubber-like materials (e.g. PVC, MDPE, XLPE)

Each type of solid dielectric material has its own physical, electrical and thermal properties that make it suited to a different type of application. Some are obviously more flexible, durable, absorb more or less moisture, and have different thermal insulating properties.

Liquid dielectrics

One of the most common uses of liquid dielectrics is in insulation and cooling for transformers, reactors, capacitors and rheostats (variable resistors used to control currents). Dielectrics in liquid form are used to prevent or slow down electric discharges. The main disadvantage of many liquid dielectrics is that they are highly flammable. While alternatives to mineral oil have been tested, such as polychlorinated biphenyls (PCBs) – these are highly toxic and were banned in the 1970s. Other liquid dielectrics such as silicone and fluorocarbon oils, are very expensive.

Examples of liquid dielectric materials include:

- Mineral oil hydrocarbons

- Silicone fluids

- Synthetic esters

Gas dielectrics

Gas dielectrics are commonly used in sealed transformers, gas-insulated lines (GILs), voltage switchgears, circuit breakers and gas-insulated transformers (GIT). The most common insulating gas, sulfur hexafluoride, is high in fluorine, which is excellent at quenching discharge and has good cooling properties. However, decomposition can produce disulfur decafluoride, which is highly toxic.

Some gas dielectrics include:

- Sulfur hexafluoride

- Nitrogen

- Air

- Carbon dioxide

- Hydrogen

Mica as a dielectric

Muscovite mica has a dielectric strength of around 2000V per millimetre. This means that a millimetre of mica can withstand 2000V before it will break down and conduct electricity. The high dielectric strength and relatively low permittivity make it an ideal choice in high voltage applications, such as capacitors, transformers and switches.

Mica also has the advantages of being resistant to high temperatures, flexible, durable, absorbing little to no moisture, as well as being cost-effective.

If you would like to find out more about how we can use mica to design and solve your high voltage insulation challenges, get in touch today.