The Benefits Of Thin Thermal Insulation

Thermal insulation is an essential process across a range of industries, but for many of its applications, there are also practical considerations to do with cost, as well as efficiency and adaptability. This is why thin thermal insulation is becoming a key area of research and development.

Space-saving as a concern in thermal insulation, is not simply limited to the construction sector. In many other industries, the benefits of thin thermal insulation are that it can have a significant impact on performance.

In the aerospace and automotive industries, for example, lightweight thermal insulation materials are essential in striking the correct balance between safety and performance.

Thermal Properties of Insulation Materials

Thermal insulation is a process, involving the reduction of heat transfer, which is the thermal transfer of energy between objects of differing temperatures when in thermal contact.

Thermal insulation helps prevent the loss of heat energy, and also helps with promoting sustainability by reducing the amount of energy fossil fuels generate. It has a huge potential for reducing CO2 emissions.

When insulation conserves energy, this generally will outweigh any energy used in the manufacture of insulation materials.

Why Thin Thermal Insulation Matters

While performance is by far the most important aspect of thermal insulation, there are other factors that can influence its effectiveness and efficiency.

One of these is ease of installation. If a thermal insulation material is too thick, rigid or heavy, this can impede its performance and also restrict its application. Another aspect is instability. Some insulation materials will shrink, compact or settle once installed. This can be an issue when considering thermal insulation for the built environment. So can moisture resistance.

Typical insulation layers add bulk. For a great many thermal insulation applications, space is a premium.

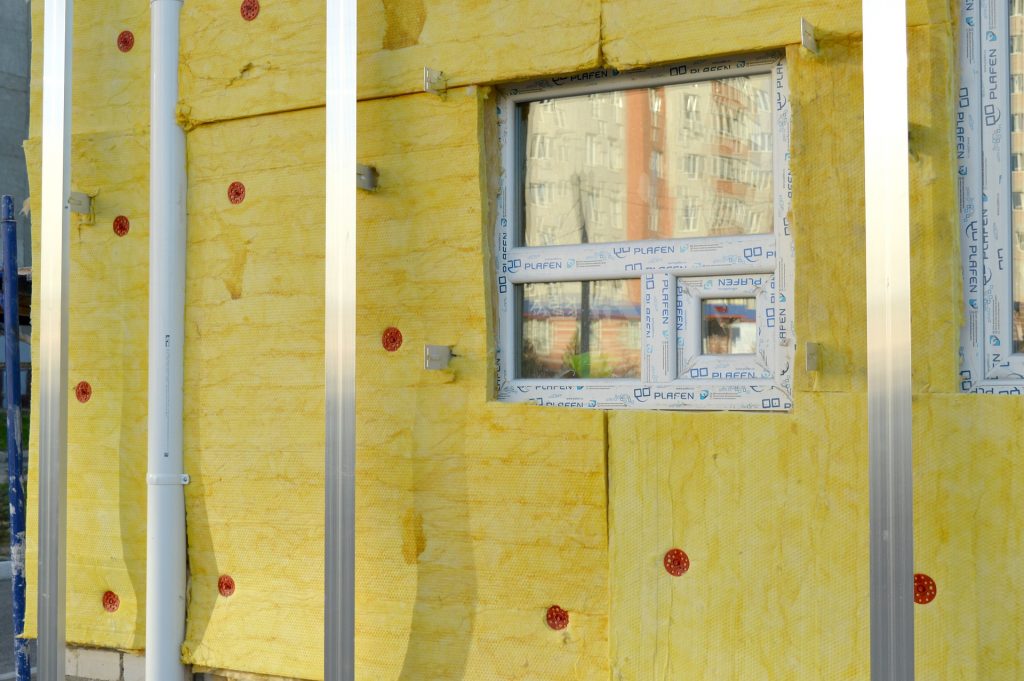

In Germany, for example, a renovation boom has meant increasing numbers of homeowners are now investing in facades to insulate their properties more effectively. While these will lower energy costs, at around 20cm thick, they alter the outward appearance of the buildings they are applied to.

These changes can also mean increased costs in other follow-up building alterations, such as fitting wider windowsills or even having to put in roof extensions.

With insulation of consumer appliances and other goods, practical considerations of size and capacity mean that thin thermal insulation is a key consideration.

Innovations in Thin Thermal Insulation

Researchers are developing materials for home insulation known as vacuum isolation panels, or VIPs. These are only 2cm thick but perform as well as traditional polyurethane foam insulation with a thickness of 15cm.

VIPs combine pyrogenic silica with high tech film to achieve this much thinner thermal insulation.

At present, there are high costs associated with the production of VIPs, which restricts their application to products where the price-point justifies the type of insulation.

There are new production methods being tested to create more cost-effective, flexible insulation films. A simplified production process, combined with larger production runs, should drive prices down.

The other area of testing this innovative thin thermal insulation is to do with longevity. The average lifespan of a refrigerator is around 12 years, which is currently how long these thermal insulation panels have been expected to last.

Eventually, the aim is to create a more long-lasting, durable material.

However, in other sectors, alternatives already exist for effective, thin thermal insulation, including microporous materials and mica.

Microporous and Mica-based Insulation

In continuous processing industries, thin thermal insulation is essential. Pipe and tube insulation in petrochemical, cement and glass processing requires thin insulation linings to ensure safe, effective passage of materials.

Lightweight, space-saving microporous sheets line petrol and chemical tubes, insulating and protecting them. Sheets come in various grades, and can withstand temperatures of up to 1600°C. Thicknesses vary according to application, but some grades of sheet are between 3mm and 50mm.

Mica in sheet form is also highly effective as a thin form of thermal insulation.

Flexible grades of mica sheet come in thicknesses of between 0.10mm and 2mm. Rigid grades are between 0.10mm and 50mm thick.

For the foundry and steel industry, having a furnace lining that can perform under intensely hot conditions, but is both strong and thin, helps increase processing capacity and protect the linings of furnaces during casting.

Another use for microporous material is in fire protection applications. It is used to line lift and fire doors to support passive fire prevention in buildings.

Again, its thinness makes it highly adaptable, while still being durable.

Thin Thermal Insulation Solutions

Elmelin specialises in thermal insulation and thermal management solutions for different industries. Our specialist manufacturing capabilities give us to source and develop bespoke insulation solutions. We also have a prototyping capability to test solutions in advance of going into full production.

Are you looking for thin thermal insulation for your product or process? Please phone us now on +44 20 8520 2248, email sales@elmelin.com, or complete our online enquiry form. We’ll get back to you as soon as possible.