Mica-Insulated Tooling

High temperature tooling insulation

Insulation is an essential enabler of processes and day-to-day working across many industries, whether it’s a production line or an individual requiring protective tools. When it comes to specialist tooling, Elmelin provides adaptable solutions, including mica-insulated heat guns, machined parts and non-mica electrical insulation.

Mica’s adaptability and versatility as a natural mineral substance mean it is ideally suited to the manufacture of specialist insulated tooling. Our advanced mica manufacturing capabilities allow us to machine-cut mica shapes and punch mica parts to order, supporting complex and demanding tooling applications.

Heat gun insulation

Electrical insulation

Machined mica parts

Custom components

Specialist mica-insulated heat guns

Heat guns are an essential tool in many industries. They are used in engineering, material science and various laboratory and workshop settings. Mica has excellent heat insulation and thermal resistant properties and can withstand temperatures of up to 1200°C, making it extremely well-suited for heating elements.

In mica-insulated heat guns, ceramic-based mica is used as an enclosing insulation around the heating element. This design enables the element to emit concentrated heat within a confined space, while the enclosing mica tube ensures uniform heat distribution – essential for consistent performance across a wide range of applications.

Customised mica components and parts

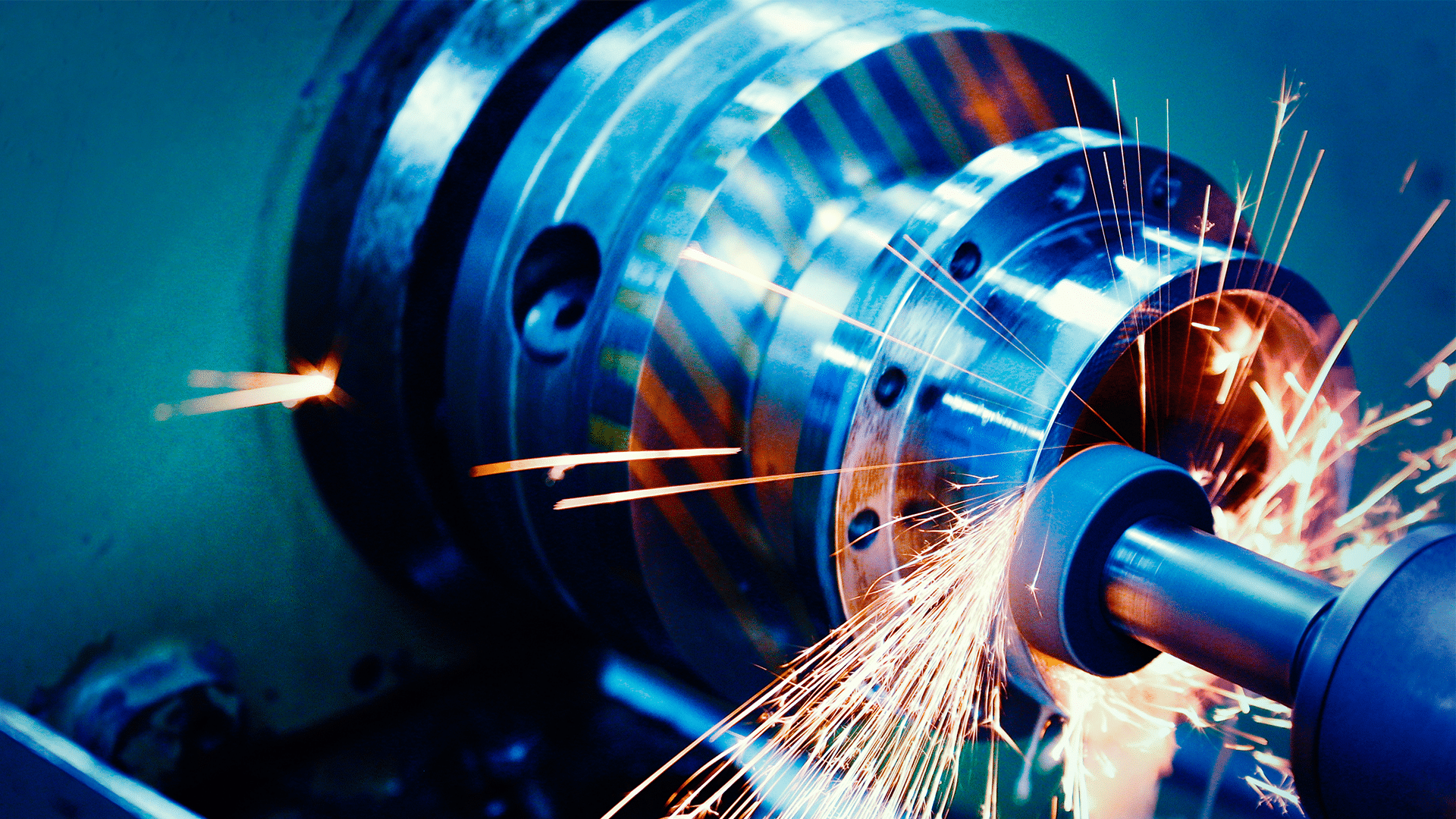

Our customised mica components and machined specialist tooling include fixtures and jigs for semiconductor manufacturing, as well as precision machined parts for lathes, grinding and milling operations. Other complex components include gaskets, washers, flanges, discs and tubes, all of which are essential to industrial processing environments.

Elmelin also manufactures punched mica parts to meet the unique specifications of our clients across a range of industries and sectors, delivering reliable performance in high-temperature and electrically demanding conditions.

Discuss your tooling insulation challenge

Frequently Asked Questions

What is mica insulated tooling?

Mica insulated tooling solutions use mica-based materials to provide thermal and electrical insulation in specialist tools and components. It is designed for high-temperature, safety-critical industrial applications.

What are the benefits of using mica for high-temperature tooling?

Mica offers excellent thermal resistance, electrical insulation and fire resistance at elevated temperatures. Its durability and stability make it ideal for demanding tooling environments.

How is mica used in heat gun insulation?

In heat guns, mica is used to enclose the heating element, allowing concentrated heat output while insulating surrounding components. This ensures uniform heat distribution and safe operation.

How does mica insulation improve safety in workshops?

Mica insulation reduces heat transfer and electrical risk, protecting users and equipment from high temperatures. Its fire-resistant properties also help minimise the risk of overheating or failure.

What temperature can mica insulated tooling withstand?

Mica insulated tooling can typically withstand temperatures of up to 1200°C. This makes it suitable for high-temperature industrial and laboratory applications.