Microporous insulation sheets

At Elmelin, we specialise in innovative microporous insulation and high temperature insulation materials that offer exceptional performance in all conditions.

Our Elmtherm range is designed to provide excellent thermal protection, space savings, and energy efficiency – whether used as a standalone solution or integrated into composite systems.

We offer different grades of Elmtherm, providing you with more choice. Our team has developed this product range through working with our customers and gaining a thorough insight into, and understanding of, the issues they face.

How microporous high temperature insulation works

Microporous high temperature insulation is based on separation technology. This involves small particles of dispersed silica creating micro-pores with diameters of less than 2nm (nanometres). The resulting sheets combine a porous structure with a low density, reducing their heat conductivity.

Microporous high temperature insulation blocks these three modes of heat transfer: conduction, convection and radiation.

Elmtherm’s microporous makeup minimises contact between molecules, reducing energy transfer from one molecule to another, and therefore reducing heat transfer due to conduction. There is also less convective heat transfer, as Elmtherm’s microporous structure creates trapped air pockets that are smaller than the free pathway of air, which would normally transmit heat through the material. Finally, this insulation also incorporates infrared opacifiers, which will reduce the amount of heat transfer from radiation.

The benefits of Elmtherm Microporous Insulation

The Elmtherm range delivers multiple operational and environmental benefits:

- Substantial energy savings and reduced carbon footprint

- Lightweight, space-efficient design

- Easy installation and handling

- Improved thermal stability and temperature control

- Enhanced performance when combined with high temperature mica based insulation

By integrating mica layers, we further increase the product’s compressive strength and thermal shielding properties, resulting in a superior industrial furnace insulation solution.

The Elmtherm range

Elmelin’s microporous insulation range includes four high-performance grades, each designed for specific temperature thresholds and applications:

Elmtherm 1000 – SiO₂ and SiO₄ silica microporous insulation, suitable for temperatures up to 1000°C. Thickness: 3–50 mm.

Elmtherm 1100 – SiO₂ and ZrSiO₄ composition, effective up to 1100°C. Thickness: 3–50 mm.

Elmtherm 1400 – Ceramic composite for enhanced high temperature insulation, withstanding up to 1400°C. Thickness dependent on application.

Elmtherm 1600 – Premium high performance microporous insulation designed for up to 1600°C, offering the highest thermal efficiency in our range. Thickness dependent on application.

Available as single sheets up to 610 mm wide and 1000 mm long, Elmtherm products are easy to install and customise to your specifications.

Frequently Asked Questions

What is microporous insulation?

What temperature can microporous insulation withstand?

How does microporous insulation work?

Is microporous insulation fireproof?

What is the thermal conductivity of microporous insulation?

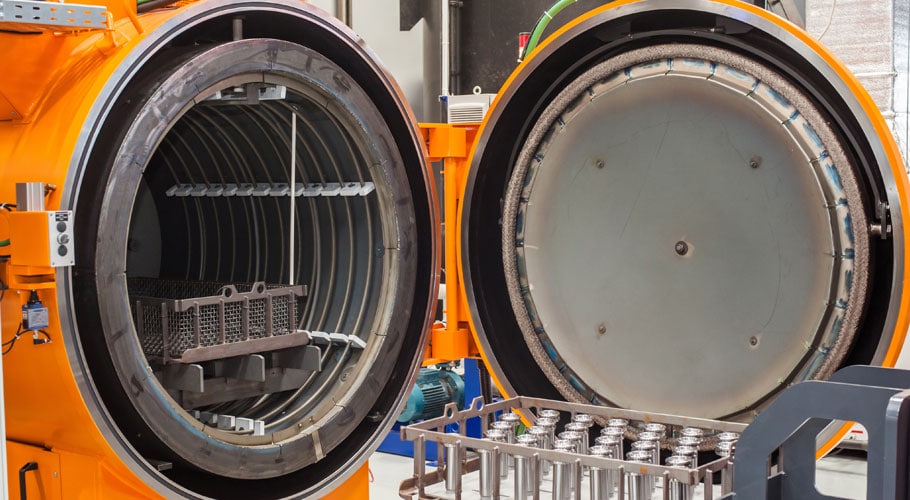

Elmtherm applications

Elmtherm’s versatility means it lends itself to a range of applications, for different sectors and industries.

- In the foundry and steel industry, Elmtherm is used to line ladles, allowing them to hold molten metal up to intense temperatures of 1650°C, increasing their capacity. This, in turn, boosts furnace productivity while taking down production costs. Elmtherm can increase ladle volume by 10% and offer a 50% improvement in energy efficiency.

- For tundishes, Elmtherm enables extended operations and continuous casting, providing both refractory and backup insulation.

It can reduce insulation thicknesses by 28mm, while lowering heat loss by some 40%. At the same time, it increases usable volume in the tundish. - In aluminium launder systems, Elmtherm optimises the movement of molten aluminium from smelter to casting, while minimising heat loss and reducing the need to superheat the metal.

- For melting furnaces, the use of Elmtherm as insulation helps ensure product quality through the even distribution of heat.

It extends the furnace’s life and offers energy savings through a 30% heat loss reduction. When compared to fibre board, its insulation is half the thickness, therefore increasing heating efficiency. - Elmtherm is also used in kilns and rotary kilns, in tunnel and reheat furnaces, and to line petrol and chemical tubes.

With consistent quality and performance, Elmtherm sets the standard for microporous insulation in modern industrial systems.

Find out more about our high temperate insulation solutions and how they could help you increase safety.