Our capabilities

Throughout our history, Elmelin have continually innovated and evolved our capabilities in order to adapt and respond to the ever-changing needs and challenges of our customers. We actively encourage a culture of innovation and experimentation that keeps us driving forward.

Our focus is developing a set of capabilities which will enable us to provide each and every customer, with the right solution for their insulation or thermal management challenge.

Lamination

We select, combine and optimise the right raw materials to deliver the precision and performance needed for the insulation application. We support customers with designing and developing bespoke mica-based laminate solutions, as well as offering our proprietary mica-based solutions, including Elmelec.

Impregnation

Our impregnation capabilities allow us to improve the resilience, performance and versatility of our mica-based insulation solutions. We can develop and manufacture mica sheets, rolls and shapes impregnated with silicone resins.

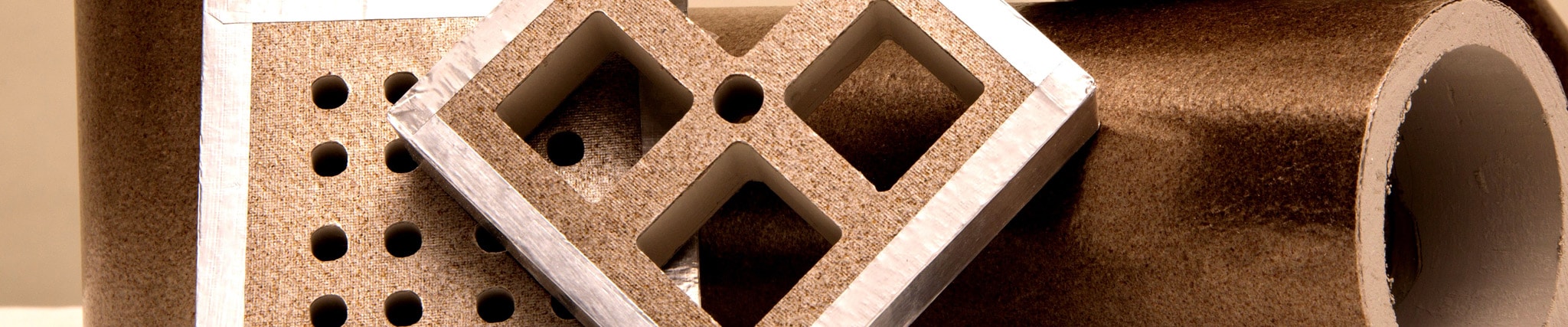

Shaping and forming of microporous insulation

Microporous insulation is an innovative solution to high-temperature thermal management challenges, particularly prevalent in the foundry industry. Our Elmtherm solution can be produced from reinforced pyrogenic silica in a range of thicknesses to meet the heat transfer capabilities needed.

Prototyping

We’ve set our processes and capabilities up to enable us to support our customers on the journey from product development all the way to manufacture. Through milling, lasering and punching, we can produce high-quality prototypes that will allow our customers to test and refine components to improve the performance of their products in very short lead-times.